Abrex 400 Plates

Product Details:

- Strength Good

- Product Type Metal

- Shape Bar

- Application Industrial

- Color Dark Brown

- Click to view more

Abrex 400 Plates Price And Quantity

- 110 INR/Kilograms

- 500 Kilograms

Abrex 400 Plates Product Specifications

- Good

- Metal

- Industrial

- Dark Brown

- Bar

Abrex 400 Plates Trade Information

- Cash Advance (CA)

- Per Day

- 1-2 Days

- All India

Product Description

The Abrex 400 Plates are made up of high grade steel that is resistant to abrasion. It has a nominal hardness of 400 HBW. It has a typical applications to various types of components and structures that are subject to wear.

Available Dimensions:

- The Hardox 400 is available in various thicknesses of 3 130mm & in widths up to 3350 mm and lengths up to 14630 mm. For widths < 1600 mm and thicknesses between 3 8 mm preferred widths are 1500 or 1600 mm.

- Hardness of HBW is according to EN ISO 6506-1, on a milled surface 0.5 -3mm below surface. Atleast one test specimen per heat & 40 tons.

Tolerances:

- The tolerance of this sheet & plate are given in SSA3's brochure 41 General product information Strenx, Hardox, Armox and Toolox UK or at WWW.SSAB.COM.

Thickness:

- The tolerances is according to SSAB's thickness precision guarantee AccuRollTech.

- AccuRollTech will meets the requirements of EN 10029 Class A & offers narrower tolerances.

- The Width is < 1600 mm & thicknesses 3 8 mm conform to EN 10051.

- Tighter tolerances will be available on customer request.

Length & Width:

- According to SSAB's dimension.

- The tolerances is according to SSAB's mill edge standards or tolerances conform to EN 10029

- Width < 1600mm and thicknesses between 3 8 mm conform to EN 10051.

- Tighter tolerances available on request.

Shape:

- The tolerances is according to EN 10029.

- Width <1600 mm and thickness 3 8 mm according to EN 10051.

Flatness:

- Tolerance according to SSAB's flatness tolerances which are more restrictive than EN 10029 Class N (steel type L)

- Width < 1600mm and thickness 3 8 mm conform with the requirements of EN 10051 but offer narrower tolerances.

Surface Properties:

- According to EN 10163 2, Class A Subclass 1

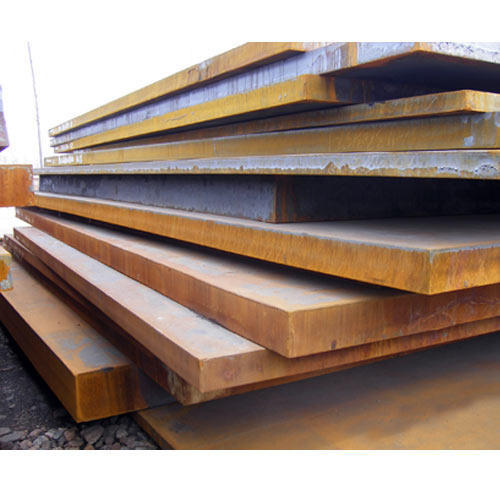

Delivery Condition:

- The delivery condition is quenched or quenched and tempered. The plates are delivered with sheared or thermally cut edges.

- The untrimmed mill edges are available by agreement. width 1600 mm and thickness 3 8mm or 80mm are delivered with mill edge as standard.

- The delivery requirements can be fond in SSAB's brochure 41 General product information Strenx, Hardox, Armox and Toolox -UK or at WWW.SSAB.COM.

Fabrication and Other Recommendations:

- Welding, bending & machining.

- The recommendations can be found in SSAB's brochures www.hardox.com

- Apart from this Hardox 400 does not require further heat treatment. It has obtained its mechanical properties by quenching and when necessary by means of subsequent tempering.

- The properties of the delivery condition cannot be retained after exposure to temperatures in excess of 250 C.

- Appropriate health & safety precautions must be taken when welding, cutting, grinding or otherwise working on this product. Grinding, especially of primer coated plates, may produce dust.

Specification Of Abrex 400 /450 /500 /600 Plates & Sheets

| Item | Abrasion Resistant Plate |

| Material | Abrex 400 /450 /500 /600 |

| Thickness | 6mm to 100mm |

| Width | 1,500mm to 2,500mm |

| Length | 6,000mm to 12,000mm |

| Heat Treatment | N, Q+T |

| Surface Paint | EP, PE, HDP, SMP, PVDF |

Specification by Type & Designation Of Abrex 400 /450 /500 /600 Plates & Sheets

| Type | Grades | Plate Thickness | Brinell Hardness (HBW)1 | Charpy Impact Test (L Direction)2 | ||

|

|

| t (mm) | Aiming | Range | Test Temperature () | Absorbed Energy (j) |

| Standard Type | ABREX 400 | 6(4.0) ~ 100 | 400 | 360 ~ 440 | - | - |

| ABREX 450 | 6(4.5) ~ 100 | 450 | 410 ~ 490 | - | - | |

| ABREX 500 | 6(4.5) ~ 100 | 500 | 450 ~ 550 | - | - | |

| ABREX 600 | 6 ~ 25 | 600 | 550 ~ 650 | - | - | |

Chemical Composition Of Abrex 400 /450 /500 /600 Plates & Sheets

| Type | Grades | Chemical Composition (%)1 | ||||||||||

|

|

| C | Si | Mn | P | S | Ni | Cr | Mo | B | PCM (t:thickness)2 | |

| t25 | t>25 | |||||||||||

| Standard Type | ABREX | 0.21 | 0.70 | 2.00 | 0.025 | 1.00 | 1.20 | 0.60 | 0.60 | 0.005 | 0.30 | 0.35 |

| ABREX | 0.23 | 0.70 | 2.00 | 0.025 | 1.00 | 1.20 | 0.60 | 0.60 | 0.005 | 0.36 | 0.36 | |

| ABREX | 0.35 | 0.70 | 2.00 | 0.015 | 1.00 | 1.20 | 0.60 | 0.60 | 0.005 | 0.42 | 0.42 | |

| ABREX | 0.45 | 0.70 | 2.00 | 0.015 | 1.00 | 1.20 | 0.60 | 0.60 | 0.005 | 0.54 | - | |

Mechanical Properties Of Abrex 400 /450 /500 /600 Plates & Sheets

| Type | Grades | Thickness (mm) | Brinell Hardness (HBW) | Mechanical Properties | ||||||

| Yield Strength (N/mm2) | Tensile Strength (N/mm2) | Bend Radius (t: thickness) | Angle | Result | Temperature () | Absorbed Energy (j) | ||||

| Standard Type | ABREX 400 | 25 | 414, 417, 416 | 1075 | 1322 | 3t |

| No Cracking | 0 | 73 |

| ABREX 450 | 25 | 458, 453, 459 | 1192 | 1469 | 3t |

| No Cracking | 0 | 57 | |

| ABREX 500 | 25 | 513, 509, 520 | 1373 | 1552 | 3t |

| No Cracking | 0 | 43 | |

| ABREX 600 | 25 | 611, 606, 601 | 1568 | 2058 | - | - | - | 0 | 13 | |